Although the Adr Group has maintained a presence in the United States for years, it has remained marginal—until now. The company has decided to hit the accelerator and pursue the same market leadership in North America that it already enjoys in Europe and in major agricultural countries outside the Eu.

More than ever, trade relations with the United States are a matter of interest not only for industry professionals and businesses, but also for public opinion. The recent stance of former President Donald Trump on import-export relations—commonly referred to as the “Tariff War”—has brought a previously niche topic into the spotlight. These dynamics affect any production company seeking to expand its commercial boundaries, including ADR. At first glance, this might seem like the reason behind ADR’s recent decision to begin manufacturing axles for the U.S. market locally, at a new plant in Iowa.

“That’s not quite the case,” explains Chiara Radrizzani, Vice President of Adr Group in charge of strategy and finance. “This project was initiated even before President Trump was elected. We conceived it to grow in a country where our axles were only marginally present, despite it being the world’s second-largest producer of agricultural commodities. It’s a paradox, considering ADR is a market leader in nearly every major agricultural country—first and foremost across Europe, but also in the UK, Brazil, Canada, Australia, China, and India. Still, we had very limited presence in the U.S. due to logistical and commercial issues that could only be resolved by operating directly on-site.”

Among these issues: long delivery times caused by having axles built in India or China, followed by slow sea freight, which affects both delivery speed and final costs.

“An American body builder might wait three to four months to receive an axle,” Radrizzani continues, “whereas with the Perry plant operational, delivery times will be cut to under 30 days—just like in Europe.”

“Exactly—and more than that,” she adds. “We’re also organizing a much more comprehensive after-sales service network and will be better positioned to meet the customization demands that are so typical of the American market. At the same time, we aim to elevate that market technologically.”

What does that mean?

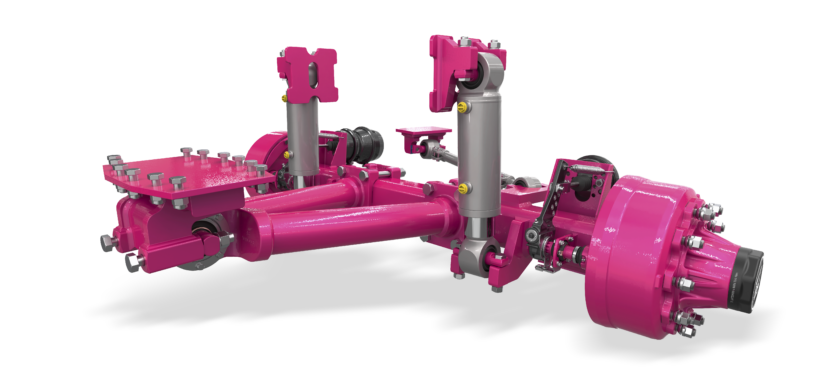

“The axles currently used by American equipment manufacturers are technologically behind those demanded in Europe. They’re often made of solid, heavy beams using low-cost steel. Wheels are always interconnected, and axles may lack brakes and suspension altogether. When suspensions are present, they are usually outdated rocker-arm types. By contrast, our axles—used around the world—are hollow, made from high-strength steel, and equipped with drum or disc brakes. They can be mounted using mechanical, hydraulic, or pneumatic systems, and offer automatic or controlled steering options. Suspensions can be interconnected or independent. For specialized applications, we even offer variable-track undercarriages.”

“Our axles can also integrate tire inflation/deflation systems and electronic components for unique digital control and management systems. Compared to what’s currently on the U.S. market, ours are like spacecraft—high-tech solutions that the market will inevitably adopt, just as it has everywhere else we’ve entered. In many of those countries, ADR is now seen not only as a quality parts supplier but as a driver of local technological advancement.”

Any examples?

“Brazil. When we started axle production in Ribeirão Preto, we realized our cutting-edge products still weren’t perfectly aligned with the needs of a sector focused on sugarcane production. That led to the development of a tailor-made axle, which today is the undisputed market leader there. In the U.S., we’re planning a similar path. We expect to grow from our current annual turnover of around 5 million euros to over 20 million within four to five years—and keep growing from there.”

So, this is a long-term vision?

“Absolutely. If ADR is now the world’s leading manufacturer of agricultural axles, it’s because we’ve always pursued growth by first exploring markets with our established products and then developing tailored solutions manufactured locally. This approach—small but consistent steps—is one we’re also applying to the industrial sector. Since 2010, we’ve been active there through the acquisition of the French company SAE-SMB, which manufactures axles for road trailers, special transport, and military trailers. Though production volumes are still limited, the quality is extremely high. These products not only contribute meaningfully to the Group’s overall revenue, but they are also helping us build the know-how that could one day lead us into the on-road transportation sector.”

Adr Axles at a Glance

The ADR Group consists of a network of companies headquartered in Uboldo, in the province of Varese, Italy. Currently, the group operates nine manufacturing facilities and six commercial branches, and it is present in over 72 countries. This structure employs about 1,500 people and, between 2020 and 2024, generated an average annual revenue of approximately 290 million euros.

A significant portion of these revenues is reinvested in R&D, carried out both in-house and in collaboration with public and private research institutions. All efforts focus on minimizing maintenance needs for off-road axles and improving the integration between mechanical, hydraulic, and electronic systems to create increasingly advanced and high-performance undercarriage control and management systems.

Title: Adr Group conquering America

Translation with ChatGPT